To detect the level of corona treatment applied to the films, Mag Data Spa suggests using specific liquids, as the TEST INK from Ferrarini & Benelli. The producer certifies that the values of dyne/cm correspond exactly to the mixture of Formammide and Cellosolve carried out according to the ASTM D 2578-84 standard. This certification is supported by sampling checks carried out using a superior grade unit called "contact angle measuring equipment”.

DEFINITIONS

Wettability: capacity of a liquid to completely spread on a flat and horizontal surface of a solid. It is measured by dyne/cm.

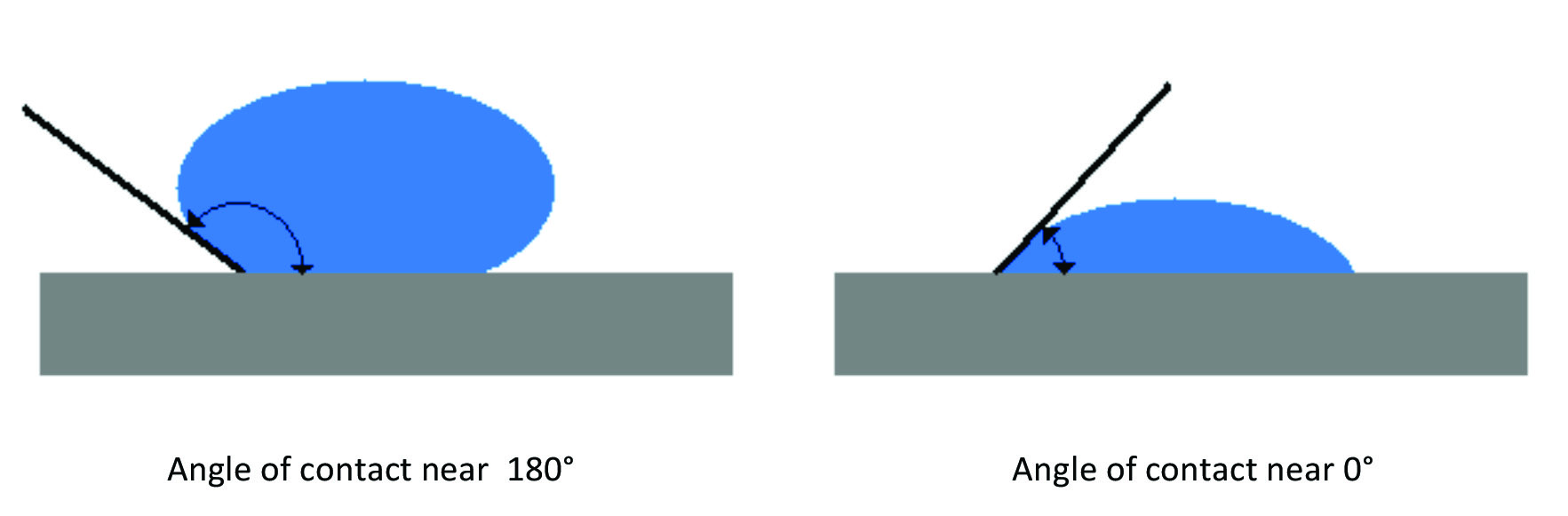

Contact angle: angle formed on the line that delimits the adhesion surface between a drop of liquid and a solid. There is complete wettability when the contact angle is close to 0° and the liquid completely covers the surface. Instead, there is poor wettability when the contact angle approaches 180° and the liquid divides into droplets. Therefore, the method requires the use of liquids with known wettability values, looking for the mixture that is at the limit of droplets formation, an indicator of the real treatment value.

Contact angle tending to 180° - Contact angle tending to 0°

PROCEDURE

To detect the level of corona treatment, a thin layer of liquid is spread with a special brush to form a strip of about 5-7cm from th treated part of the film. At this point, measure the time taken from the liquid to break into droplets. If the surface layer of the liquid has not yet changed after two seconds, it means that the wettability of the sample is higher than the value of the liquid used. To determine the exact wettability value you should use a mixture with a higher value until it remains spread for two seconds. In this case the wettability of the film corresponds to the value given for the liquid used for the test. Conversely, if the liquid breaks into droplets in less than two seconds, it is better to use a liquid with a lower value.

NOTE: all tests must be performed using vergin samples, i.e. not previously tested. The test carried out by an expert operator obtains a precision of ±0.5dyne/cm. Finally, it is suggested to carry out the test in environmental conditions of 23° ± 2°C, with a relative humidity of approximately 50% ± 5%.

PRECAUTIONS

The above mentioned products cause skin irritation. Therefore it is necessary to avoid any direct contact and to protect the eyes. Always keep the container closed as the evaporation of the Cellosolve (one of the components) changes the composition of the mixture.

STORAGE

It is recommended storing the product away from heat sources and direct sunlight. The ideal is to keep the bottles inside their box in a ventilated place. It is also recommended closing the bottle immediately after brushing.

EXPIRY DATE

The expiration date of the liquids is not easily quantifiable since it depends on how long the bottles are left open. However, it is advisable to replace the test Ink every six months so as to guarantee perfect measurement.

NOTE: the dyne/cm values indicated on the container correspond exactly to the mixing of Formammide and Cellosolve carried out according to the ASTM D 2578-84 procedure. This certification is supported by sampling checks carried out using a high class instrument called “contact angle meter”.

SOURCE: Ferrarini & Benelli.